Key Takeaways

- A well‑maintained boiler can reach 40‑50years, but most factors determine the exact end point.

- Material, type (condensing vs non‑condensing), installation quality, water quality and regular service are the biggest drivers.

- Typical lifespans: cast‑iron (45‑55yr), stainless‑steel (30‑40yr), modern condensing units (15‑20yr) if neglected.

- Watch for noises, leaks, pressure fluctuations and rising energy bills - they often signal an impending failure.

- When repair costs exceed 50% of a new boiler price, replacement usually makes more sense.

Homeowners constantly wonder whether a heating system can truly survive half a century. The short answer is boiler lifespan can stretch to 50years, but only under a specific set of conditions. Below we break down every factor that pushes a boiler toward that golden milestone, and we’ll show you how to decide when it’s time to keep fixing and when to start shopping for a new unit.

What Exactly Is a Boiler?

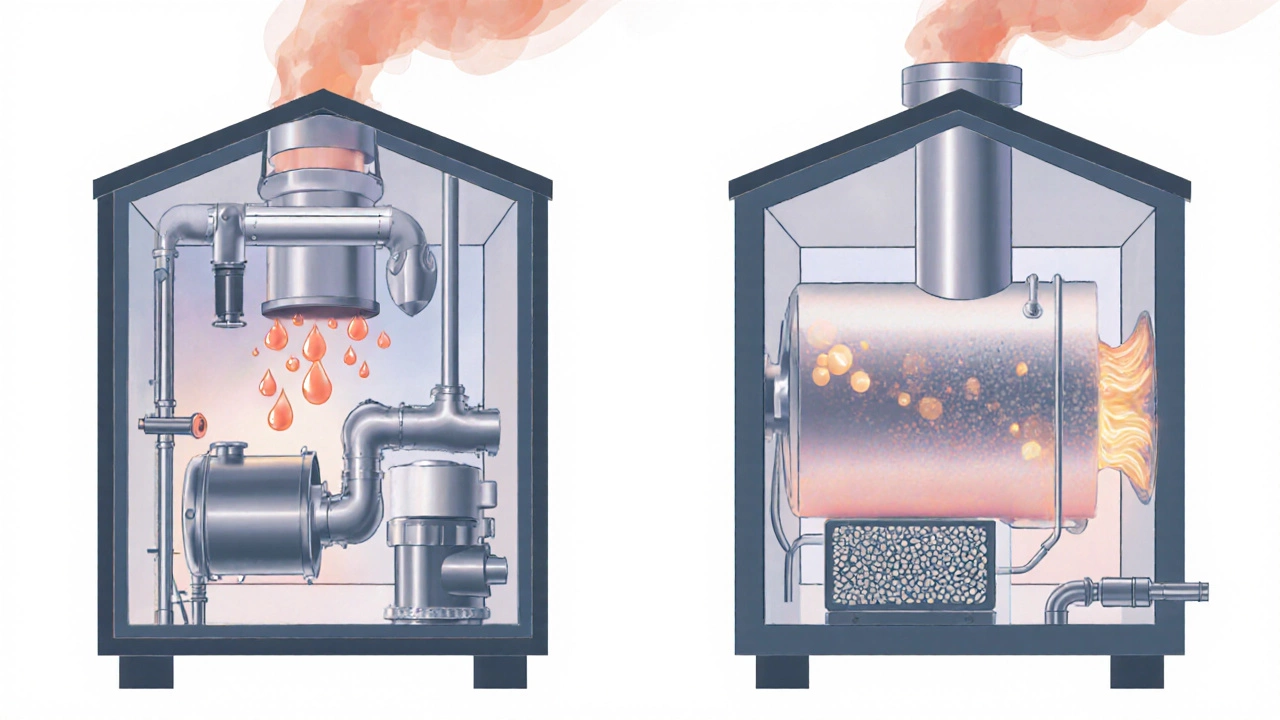

In the simplest terms, a boiler is a closed vessel that heats water for domestic heating and hot‑water supply. In NewZealand most homes use gas‑ or oil‑fired models, although electric and biomass options exist. The boiler’s job is to convert fuel into heat, transfer that heat to water, and circulate the hot water through radiators or underfloor pipes.

Materials and Construction: The Core Longevity Drivers

Older boilers were often built from heavy‑duty cast iron. A cast iron boiler features thick walls and a high resistance to corrosion, giving it a natural advantage in durability. Modern units tend to use stainless steel or aluminium, which are lighter and more efficient but can be more vulnerable to scaling and galvanic corrosion if water treatment is neglected.

Another critical distinction is between condensing boiler a high‑efficiency system that extracts heat from exhaust gases, achieving efficiencies above 90% and non‑condensing boiler which expels hot exhaust directly, typically hitting 70‑80% efficiency. Condensing units are great for energy savings, yet they operate at lower return‑water temperatures, which can increase acid condensation inside the heat‑exchanger if the water chemistry is poor. That internal wear can shorten the usable life compared with a robust cast‑iron design.

Typical Lifespans by Boiler Type

| Boiler Type | Typical Lifespan | Key Maintenance Needs |

|---|---|---|

| Cast Iron Boiler | 45‑55years | Annual flushing, corrosion inhibitor, pressure checks |

| Stainless Steel Boiler | 30‑40years | Water softening, regular burner cleaning |

| Condensing Boiler | \n15‑20years (if neglected) / 25‑30years (with diligent care) | Acid neutralizer, yearly service, low‑temperature system checks |

| Non‑Condensing Boiler | 20‑25years | Burner tune‑up, pressure valve inspection |

How Maintenance Extends Life

Maintenance isn’t a luxury-it’s the difference between a 20‑year run and a 50‑year run. Below is a practical checklist you can hand to your service technician or use yourself if you’re comfortable with basic plumbing.

- Schedule an annual boiler service a comprehensive inspection, cleaning, and performance test performed by a qualified technician. This catches wear before it becomes failure.

- Inspect the boiler pressure valve the safety device that releases excess pressure, preventing catastrophic leaks for corrosion or wobble.

- Flush the system every 3‑5years, especially if you have hard water. Use a professional descaling kit or hire a specialist to avoid damaging the heat‑exchanger.

- Install a water softener a device that reduces calcium and magnesium ions, limiting scale buildup inside the boiler if your water hardness exceeds 150ppm.

- Check the thermostat and room‑temperature sensors for accuracy; inaccurate readings force the boiler to cycle more often, increasing wear.

Warning Signs That the Boiler Is Nearing the End

Even with diligent care, boilers eventually show tell‑tale symptoms. Spotting them early saves money and prevents a cold home on a winter night.

- Kettling or gurgling noises - indicates scale or air trapped in the heat‑exchanger.

- Persistent leaks around the pressure valve, pipe joints, or the boiler shell - corrosion may have compromised the metal.

- Frequent short‑cycling (boiler turns on and off quickly) - can be caused by an oversized unit, faulty thermostat, or low‑water pressure.

- Rising energy bills without a change in usage - the system is working harder because efficiency has dropped.

- Water stains or rust on radiators - points to internal corrosion that may also affect the boiler body.

Repair vs. Replace: The Cost Equation

When you get a repair quote, compare it to the cost of a new, energy‑efficient boiler. A rule of thumb used by many NZ technicians is the “50% rule.” If the repair cost is more than half the price of a comparable replacement, it usually makes financial sense to install a new unit.

Consider also the long‑term savings. A modern condensing boiler can be 15‑20% cheaper to run than an aging non‑condensing model. Over a 10‑year period, that efficiency gain often offsets the higher upfront price.

Real‑World Example: A Wellington Home

John and Maya bought a 1978 cast‑iron gas boiler when they moved into their 3‑bedroom house in Wellington. They performed an annual boiler service every year, added a water softener in 2005, and flushed the system in 2012. The boiler is now 47years old and still provides reliable heat, with only minor burner tuning required last summer. Their story illustrates that, with the right upkeep, a cast‑iron boiler can easily hit the 50‑year mark.

Contrast that with a neighbor who installed a cheap 2015 condensing unit, skipped the yearly service, and used hard water without treatment. By 2023 the boiler started leaking and the efficiency dropped to 68%. A replacement was inevitable after just eight years.

Bottom Line: Can a Boiler Last 50 Years?

Yes-if you choose a durable material (cast iron or high‑grade stainless steel), keep the water clean, and commit to regular professional service. Neglect, hard water, and poor installation will shave years off even the toughest boiler.

Next Steps for Homeowners

- Locate the installation date on the boiler’s nameplate or service log.

- Schedule a thorough inspection with a licensed NZ boiler technician.

- Assess water hardness; if needed, install a water softener.

- Set a calendar reminder for annual service and a 5‑year system flush.

- When the repair quote approaches 50% of a new unit’s price, start researching energy‑efficient replacements.

Frequently Asked Questions

How often should I have my boiler serviced?

At least once a year, preferably before the heating season starts. Annual service checks pressure, burner efficiency, safety valves, and signs of corrosion.

Does a condensing boiler really last less than a cast‑iron one?

Condensing boilers can last as long as any other type if you control the water chemistry and schedule regular maintenance. Their internal heat‑exchanger is more susceptible to acidic condensation, so a neutralizer and yearly service are essential.

What are the signs that my boiler is about to fail?

Listen for kettling noises, watch for leaks, notice any short‑cycling, monitor rising energy bills, and check for rust stains on radiators. Any of these should trigger a professional inspection.

Is it worth installing a water softener for my boiler?

If your water hardness exceeds 150ppm, a softener can dramatically reduce scale buildup, extending the boiler’s life by 10‑15years and keeping efficiency high.

How do I calculate whether to repair or replace?

Compare the repair quote to 50% of a comparable new boiler’s price. Factor in expected energy savings from a new, higher‑efficiency unit. If the repair exceeds that threshold, replacement is usually smarter.

I am an expert in the services industry with a focus on appliance repair. My passion lies in understanding how things work and educating others in simple, engaging ways. This enthusiasm fuels my writing, where I delve into topics around appliance maintenance and troubleshooting. I aim to make these subjects clear and accessible to all readers.