Extractor Fan CFM Calculator

Calculate Your Kitchen's Airflow Needs

This calculator helps determine the minimum CFM (cubic feet per minute) needed for proper kitchen ventilation based on your kitchen size and cooking habits.

Recommended Airflow

Minimum CFM Needed:

Your Fan's Performance:

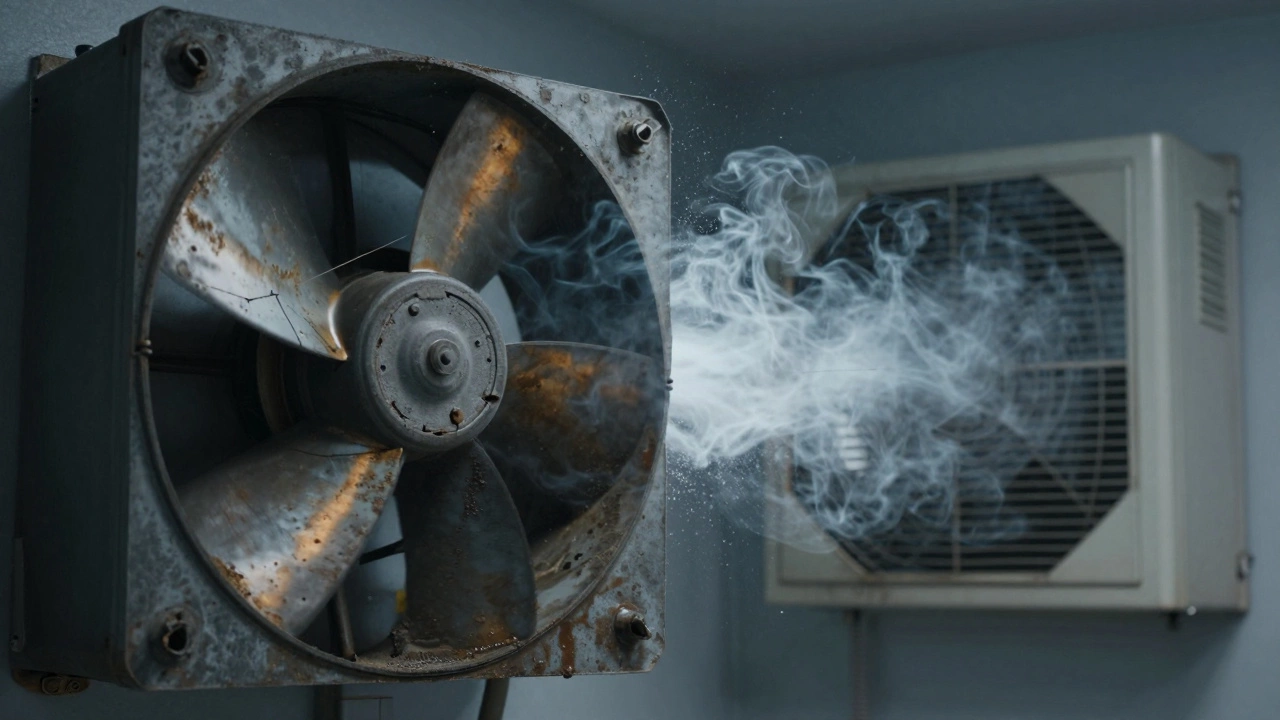

If your extractor fan is quiet when it should be roaring, or you still smell grease and steam after cooking, it’s not working right. A faulty extractor fan doesn’t just make your kitchen unpleasant-it can lead to mold, ruined cabinetry, and even health issues from trapped moisture and pollutants. You don’t need a professional to check it right away. Most problems are simple to diagnose and fix yourself.

Turn it on and listen

The easiest first step is to switch the fan on. Listen closely. If you hear nothing at all, the problem could be power-related. If you hear a hum but no airflow, the motor might be struggling. A rattling or grinding noise means something’s loose or worn out. A properly working extractor fan should start up smoothly and run with a steady, consistent sound-not a sputter or a whine.Try running it on all speed settings if your model has them. If it works on high but not on low, the speed control switch is likely faulty. If it doesn’t turn on at all, move to the next checks.

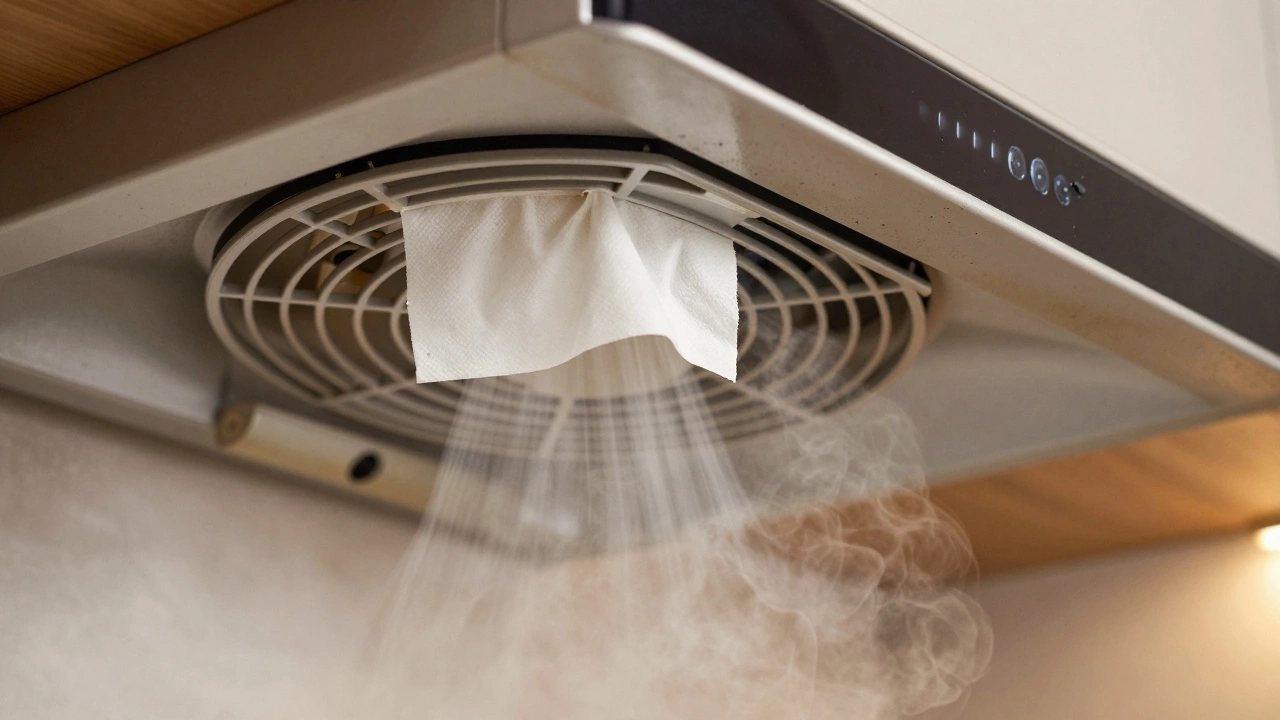

Check for airflow at the outlet

Go outside or to the roof vent where the fan exhausts. Hold a piece of tissue paper or a lightweight kitchen towel against the vent grille. If the fan is working, the paper should be pulled firmly against the grille. If it flops around or falls, there’s little to no airflow.Don’t rely on feeling air with your hand-wind, temperature, or building pressure can fool you. The tissue test is reliable. If the paper doesn’t stick, the fan might be clogged, the duct is blocked, or the motor has failed.

Inspect the duct for blockages

Most extractor fans fail because of grease and dust buildup inside the duct. Over time, cooking vapors condense and stick to the inside of the ductwork. In kitchens with heavy frying or roasting, this can happen in under a year.Turn off the power at the circuit breaker. Remove the fan cover and look into the duct opening. If you see thick, greasy residue, that’s your culprit. Use a long brush or vacuum with a narrow nozzle to clean it out. If the duct is made of flexible plastic or foil, check for kinks or crushing-these choke airflow even if the motor runs fine.

For rigid metal ducts, you might need to disconnect sections to clean properly. If you’ve never cleaned the duct in more than two years, it’s overdue.

Test the switch and wiring

If the fan doesn’t turn on at all, the issue could be the wall switch, pull cord, or wiring. Start by checking if other appliances on the same circuit are working. If they’re not, the circuit breaker might have tripped.Flip the switch on and off a few times. Sometimes a sticky switch just needs a little jolt. If that doesn’t help, turn off the power and remove the switch cover. Look for loose wires, burnt terminals, or corrosion. If you’re not comfortable working with wiring, skip this step and call an electrician.

Some extractor fans have a built-in timer or humidity sensor. If the fan only runs for 10 minutes after you turn it on, that’s normal. But if it won’t stay on, the timer module may be faulty. Replace it if you can find the model number and a compatible part.

Check the fan blade and motor

With the power off, remove the fan cover and inspect the blades. Are they covered in thick grease? Clean them with warm soapy water and a soft brush. If the blades are cracked, bent, or wobbling, replace them. A damaged blade can throw the motor out of balance and cause premature failure.Spin the blades by hand. They should turn freely without grinding or resistance. If they’re stiff, the motor bearings are likely worn. You might hear a dry squeak when you spin them. That’s a sign the motor is nearing the end of its life. Most extractor fan motors last 5-8 years. If yours is older and the bearings are gone, replacing the whole unit is often cheaper than repairing it.

Verify the backdraft damper

Every extractor fan has a backdraft damper-a flap that opens when the fan runs and closes when it stops. This stops cold air, pests, and smells from coming back into your kitchen.If the damper is stuck shut, the fan won’t exhaust air properly. If it’s stuck open, you’ll get drafts and noise from outside. To check it, remove the external vent cover (from outside the house) and look at the flap. It should swing open easily when you blow into the duct. If it doesn’t move, clean off any grease or debris. If it’s broken, replace the damper assembly. Many manufacturers sell replacement dampers for under $30.

Compare performance to manufacturer specs

Look for the fan’s CFM (cubic feet per minute) rating on the label or manual. A standard kitchen extractor fan should move at least 100 CFM. For larger kitchens or heavy cooking, aim for 150-200 CFM.If your fan is rated for 150 CFM but the tissue test shows weak airflow, it’s underperforming. This could be due to a dirty filter, blocked duct, or weak motor. If the fan is old and underpowered, upgrading to a newer model with higher CFM and better energy efficiency might be the best long-term fix.

When to call a professional

You can fix most extractor fan issues yourself-but there are times to call in help:- You smell gas or burning plastic near the fan

- The fan trips the circuit breaker every time you turn it on

- You’re unsure about working with electrical wiring

- The duct runs through the roof or wall and you can’t access it safely

- You’ve cleaned everything and the fan still doesn’t work

Electricians and appliance repair technicians can test motor amperage, check for hidden duct leaks, and replace internal components you can’t reach. Don’t risk shock or fire by forcing a broken fan to work.

Prevent future problems

Once your fan is working again, keep it that way:- Wipe down the filter every week

- Deep clean the blades and duct every 3-6 months

- Replace charcoal filters every 6 months if you have a recirculating model

- Run the fan for at least 15 minutes after cooking to clear moisture

- Install a timer switch so it doesn’t get forgotten

A well-maintained extractor fan lasts longer, uses less electricity, and keeps your kitchen air clean. It’s a small task that saves big headaches down the line.

Why does my extractor fan run but not pull air?

If the fan spins but doesn’t move air, the duct is likely blocked by grease, the backdraft damper is stuck, or the fan blades are caked in grime. Clean the duct and blades thoroughly, and check that the external vent flap opens freely. A weak motor can also cause low airflow, especially in older units.

Can I use my extractor fan without a filter?

You can, but you shouldn’t. Filters trap grease and particles before they enter the duct. Without one, grease builds up inside the motor and ductwork much faster, leading to clogs, fire risk, and motor failure. Always use the correct filter for your model-metal mesh filters are washable, charcoal filters need replacing every 6 months.

How do I know if my extractor fan is powerful enough?

Check the fan’s CFM rating, usually printed on a label inside the unit or in the manual. For a standard kitchen, aim for at least 100 CFM. For larger kitchens, open-plan spaces, or if you do a lot of frying, go for 150-200 CFM. If your fan is older than 10 years, it’s probably underpowered by today’s standards-even if it still runs.

Why does my extractor fan make a loud buzzing noise?

A loud buzz usually means the motor is failing or the fan blades are unbalanced. First, turn off the power and clean the blades-grease buildup can throw them off balance. If the noise continues, the motor bearings are worn. Repairing the motor is rarely cost-effective. Replacing the whole unit is usually cheaper and quieter.

Should I replace my extractor fan or just repair it?

If the fan is less than 5 years old and the issue is a dirty filter or blocked duct, clean it. If it’s older than 8 years and the motor is noisy or weak, replacement is better. Modern fans are 30-50% more energy efficient, quieter, and come with better filters and timers. Paying to repair a 10-year-old fan often costs more than buying a new one.

I am an expert in the services industry with a focus on appliance repair. My passion lies in understanding how things work and educating others in simple, engaging ways. This enthusiasm fuels my writing, where I delve into topics around appliance maintenance and troubleshooting. I aim to make these subjects clear and accessible to all readers.